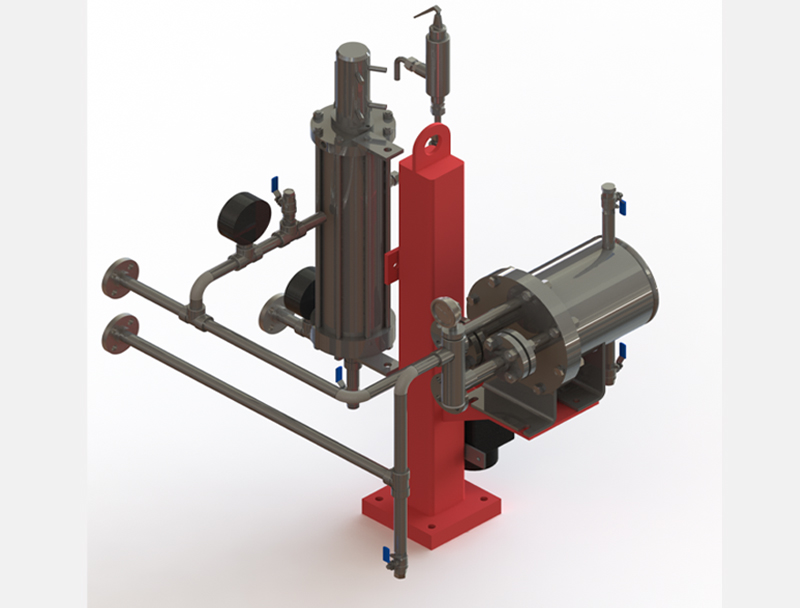

Seal Support System

API PLAN 53C

API PLAN 53C

Production Description

- API Plan 53C is pressurised piping plan where the stuffing box pressure is variable. It consists of piston accumulator, heat exchanger either water or air cooled, instrumentation like Pressure Gauge, pressure relief valve, level sensor and pipe fittings

Objective

- It is used for arrangement 3 Seals in which the stuffing box pressure is variable

- Also used in application with high temperature and variable stuffing box pressure

- It is the fool – proof API Plan where the barrier pressure will always be maintained at 2 Kg/Cm2 above box pressure there by maintaining differential pressure across the faces

- It is used for the most critical equipment where must-run is required

- It is used for application where contrition is contained within the closed circuit

Advantages

- Only Mechanical system is used to achieve 2 Kg/Cm2 above any stuffing box pressure.

- The make-up system can supply pressurized barrier fluid to multiple dual pressurized sealing systems with either like on unlike pressure conditions.

- The make-up system pressurizing the barrier fluid is not subjected to nitrogen or air entrapment as with API Plan 53A

- Can be used for high temperature applications also

- Compact and easy for maintenance.

Technical Features

- Piston accumulator along with spring design to create 2 Kg/Cm2 extra pressure than the reference applied pressure

- A reference line from the seal chamber to a piston accumulator that provides a constant pressure above the seal chamber pressure.

- Spring force with or without bellow load provides the additional constant pressure during equilibrium

- Flow rate of the circuit is controlled by the pumping ring design, peripheral speed, barrier fluid viscosity and resistance of the piping circuit.

- Tangential outlets should be used to enhance the flow rate of the pumping ring

- Make-up system using hand-pump is available