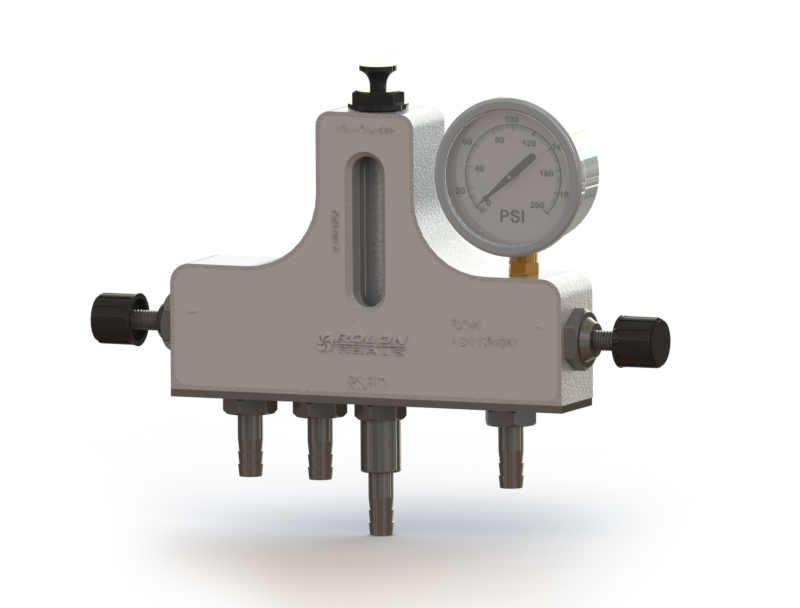

Seal Support System

Flow Control Device

Menu

Flow Control Device

Production Description

-

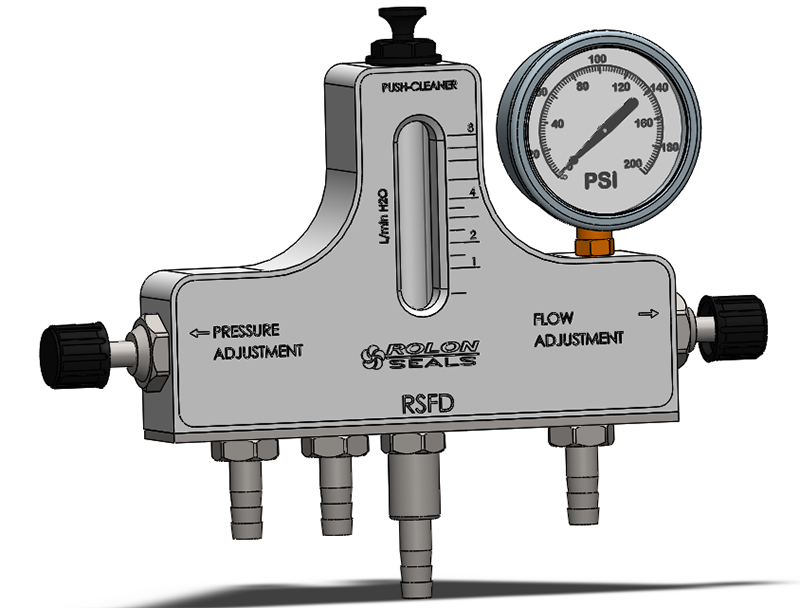

1. Flow Control Device is specifically designed to supply uninterrupted, regulated seal flush water and deliver operational efficiency to the pump population can also regulate flow and pressure and is ideal for single & dual seals installations, or when inboard seal failure detection is of less importance

2. The clog resistant valve construction combined with a simple measuring principle and wide flow channels have especially been optimized to withstand contaminated seal water

Objective

- Managing flow rates while regulating important pressure differentials is possible.

- Costly seal failures are reduced while assisting in plant water conservation initiatives.

- It is designed to measure flow entering and exiting a dual seal installation.

- This capability allows for early detection of leakage into the process stream as a result of inboard seal failure.

Typical Industrial Application

- Pulp & Paper Industry

- Water & Waste water Industry

- General Industry

- Single and double mechanical seals

- Gland packings

- Flush water

- Purging

- Other flow measurement

Advantages

- Built-in pressure regulator Innovative plunger cleaner Oil filled pressure gauge Rugged, compact design Tamper proof locking system Alarm sensor-ready Excellent corrosion resistance Rebuild kits available Optional barb or compression fittings

Operating Parameters

- Flow Rate : 0,1 – 3 liters/min / 2 – 50 US gallons per hour

- Pressure Limits : 10 bar g / 145 psig*

- Temperature Limits :100°C / 212°F

Material of Construction

- Flowmeter Tubes : Polysulfone (PSU)

- Body of Unit : Polyoxymethylene (POM) Stainless Steel Case

- O-rings : Fluorocarbon (FKM)

- Pressure Gauge : Oil filled with 316SS and Wetted Parts, 1/4 ” – NPT Bronze fitting

- Pressure Regulating Valve : 316 Stainless Steel / EN 1.4401

- Flow Rate Regulating Valve : 316 Stainless Steel / EN 1.4401

- Clean-out Plugs : 320 – 3/8″ Tube Fittings (for compression connections) 316 – Optional Barb Fittings

- Mounting Bracket : 316 Stainless Steel / EN 1.4401