Seal Support System

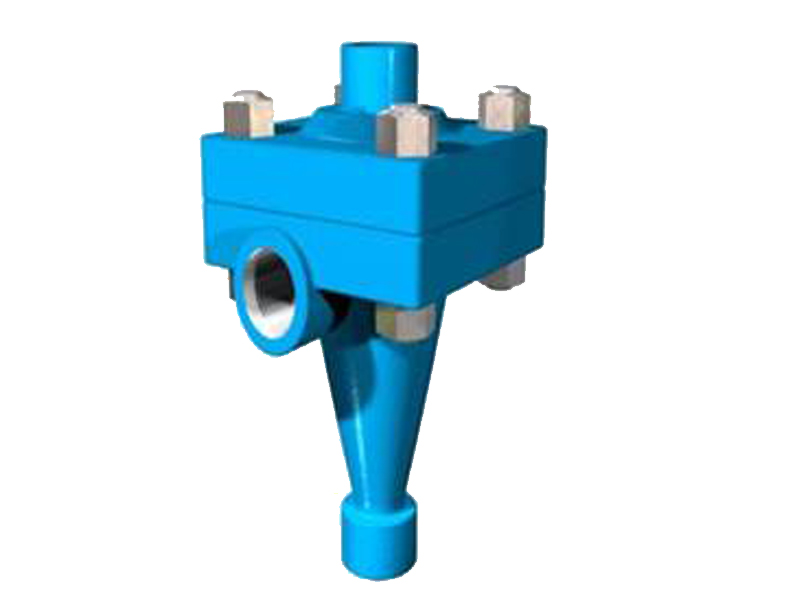

Cyclone Separators

Menu

Cyclone Separators

Production Description

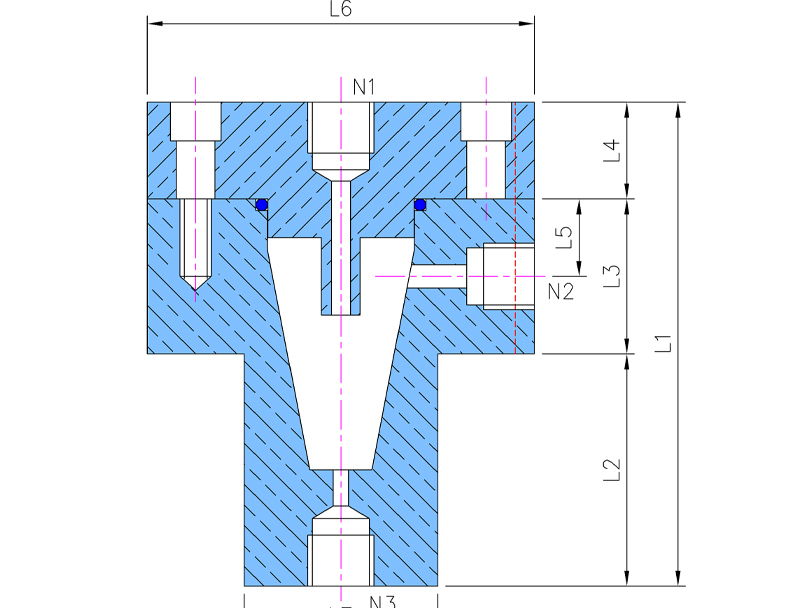

- Cyclone separator is a Mechanical device either machined or cast in structure. The lower body and the upper body is sealed with an elastomeric O-ring and is connected with the help of studs and nuts. The internal diameter of the cyclone separator gradually tapers down. It has three ports – inlet, outlet, drain.

Objective

- Cyclone separator is used for removal of dirt and solid particle from the flush liquid so that clean liquid reaches to the mechanical seal or to designed source.

- It is also used in combination with restriction orifice plate to provide pressure drop and supply the clean liquid with required pressure to the mechanical seals.

Advantages

- Contaminations including dirt & solid particles are automatically conveyed to the suction nozzle.

- No consumption of electricity owing to complete mechanical design.

- High filtration efficiency

- Low space requirements because of compact design

- Provides exact required pressure differential with the help of orifice plate.

Technical Features

- Tangential entry of liquids containing solid particles provides sufficient centrifugal force to create a vortex allowing solid particles to spiral down due to difference in densities of liquid & solid particle.

- Separation efficiency is maximum when the density of the solids is at least double than that of flush liquid.

- Operates at best when the minimum pressure differential between discharge and stuffing box is 1.7 bar.

- Used in combination with orifice plate to achieve required pressure to be provided at the Seal faces